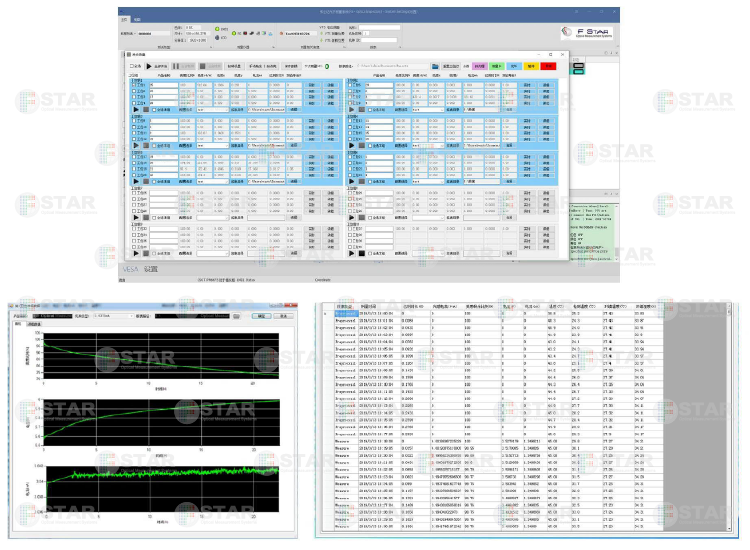

OLED Panel Lifetime + White Balance + I-V-L Testing System

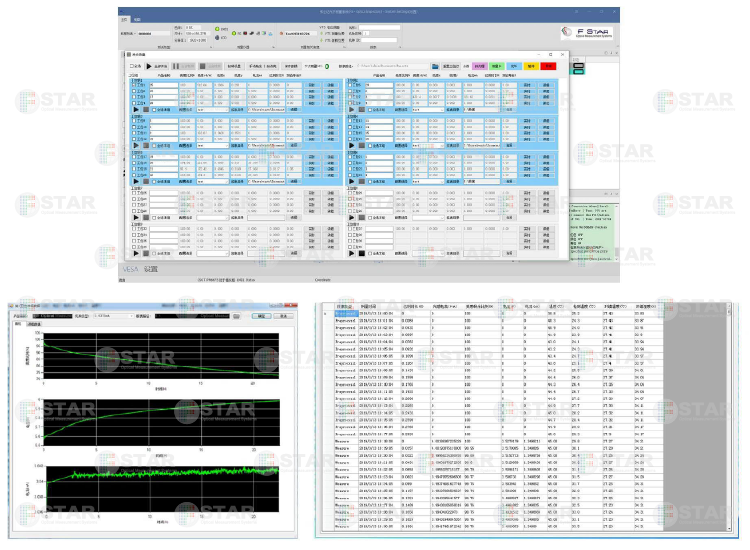

This system can control the Panel PG to adjust the input voltage on the Panel Pad of each bonding station, thereby achieving appropriate luminance and chromaticity. This process of adjusting luminance and chromaticity is called white balance adjustment. Then, it measures the lifetime curve of the Panel under this luminance and chromaticity. I-V-L testing of the Panel is 穿插 before and after the lifetime test, with the Panel PG outputting the test power supply. It realizes long-term room-temperature lifetime testing, high-temperature lifetime testing, luminance and chromaticity uniformity testing (with customizable multi-point positions), and I-V-L measurement functions.

System Composition

- Darkroom Measurement Platform (including 3-axis motion control system)

- Spectroradiometer

- Temperature and Humidity Meter

- Automatic Visual Positioning System

- Multi-Panel Signal Generator

- Multi-station Power Meter

- Alignment Machine

- Complete set of fixtures, FPCs, and adapter PCBs for Panel bonding

- Panel Temperature Control System (including chamber heating and base plate heating, optional)

- Darkroom Infrared Monitoring System

- Industrial Computer

- OLED Testing Software

System Features

- Mature and stable motion control system: 100Mbps real-time Ethernet high-speed communication with a communication response as low as 50ms; motion accuracy up to 0.1mm; capable of long-term non-stop operation.

- Accurate data collection: Fully enclosed darkroom with an environment as low as 0.1Lux; temperature sensors installed in the darkroom for real-time monitoring of the internal temperature; high-precision spectrometer ensuring accurate measurement data.

- Automatic positioning: A 5-megapixel industrial camera automatically determines the product placement position, accurately locates the product’s center point with a deviation as low as 0.1mm.

- Air-heated high-temperature chamber: One chamber can test 5 products simultaneously.

Measurement Items

- The equipment adopts an independent test channel and uses a spectrometer for optical lifetime testing of OLED cells, connected to an independent test system.

- Cell lifetime testing: Heat the chamber to test the lifetime of cells under different temperature environments (RT~100℃).

- Cell I-V-L measurement: Use an external multi-station power meter (Keithley 3706A) to read the voltage and current for I-V-L testing.

- Cell fixtures achieve bonding through FPC (Flexible Printed Circuit) bonding, and use a semi-automatic alignment machine to meet bonding testing requirements for both flexible and rigid products, ensuring accurate bonding.