Imaging Colorimeter and Viewing Angle Analyzer VA-6100UL

Traditional optical testing of displays includes items such as luminance, chrominance and uniformity; viewing angle and color shift; WRGB color gamut and color temperature; grayscale Gamma; DeltaE color accuracy; grayscale response time; and MPRT. To complete these tests, users typically require a complex fully automatic optical testing system, which consists of a five-axis testing machine, spectrometer, grayscale response time meter, imaging luminance and chrominance meter, and other instruments. However, such five-axis optical systems have drawbacks including complex fixing mechanisms for the test screen, long testing time, and cumbersome operation.

To improve testing efficiency while ensuring measurement accuracy, miniaturize the testing system, present more intuitive and reasonable viewing angle data characteristics, and enhance user experience, Fstar has launched the Imaging Luminance, Chrominance and Viewing Angle Analyzer VA-6100UL. It innovatively integrates a spectrometer, imaging luminance and chrominance meter, grayscale response time meter, imaging lens, viewing angle analysis conoscopic lens, and other components into a single instrument. With only a small space and a simple darkroom platform, it can perform comprehensive optical testing and analysis for displays of various shapes and types, making it a powerful tool for optical research and testing of display screens.

High-Resolution Image Sensor

A 61-megapixel high-resolution cooled CMOS sensor optimizes resolution and dynamic range to ensure imaging performance, delivering accurate and repeatable measurement results.

High Speed and High Sensitivity

The chip integrates a dual-stage semiconductor cooler and unique dark current noise control technology, minimizing measurement noise and drift. It enables precise analysis of weak light signals with extremely high sensitivity.

Electronic Lens Control

The system hardware integrates a focus drive module, allowing electronic control of focal length and the EMD electromagnetic drive aperture unit in the lens via software. It automatically adjusts exposure and related parameters to find the optimal test image, easily adapting to different testing environments.

High-Resolution Viewing Angle Measurement System

The conoscopic lens achieves a viewing angle resolution of up to 0.03°, with high precision at every viewing angle. It can measure luminance, angular contrast, CIE chromaticity coordinates, and correlated color temperature (CCT).

Rapid ±80° Viewing Angle Measurement

Complete cone-shaped viewing angle data within the ±80° range can be collected in a single measurement, providing accurate results quickly.

Built-in Grayscale Response Time Meter

Delivers MPRT test results compliant with the IDMS standard; equipped with a built-in Hamamatsu PMT photoelectric sensor probe with extremely high sensitivity. It features a built-in Y filter that matches the human visual function curve, ensuring excellent luminance linearity. A 1MS/s data acquisition card is used to collect photoelectric change data, with a minimum sampling time of 1μs. Built-in ND filters and gain control enable a minimum luminance limit of 0.001cd/㎡.

Laser Distance Measurement

Measures the distance from the lens to the product, facilitating automatic height adjustment during different tests. When using the conoscopic lens, it precisely controls a 1mm measurement distance.

Automatic Alignment

With the sample as the reference, the camera analyzes the alignment image and automatically aligns.

Multiple Fixed-Focal Lens Options

Standard configuration: 50mm lens; Optional: 35mm, 85mm, 105mm, macro lens, AR/VR lens, conoscopic lens.

Multi-Signal Integration

Provides motion image driving signals for test display samples. Supports the following types:

• Android, iOS, and Windows systems;

• Custom development for programmable pattern generators.

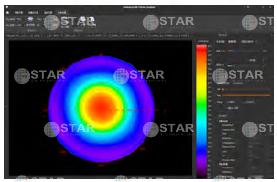

Fstar has applied for a design patent for the conoscopic lens. A single measurement can obtain the viewing angle distribution map of chrominance, luminance, and contrast of the test display screen within the ±80° range, with a viewing angle resolution of 0.03°/pixel. Typically, it takes only about 20 seconds to complete comprehensive viewing angle testing for displays with luminance above 100cd/m², with reports output at 1° or 0.1° intervals. Compared with obtaining viewing angle data by rotating the spectrometer or display screen, the use of the conoscopic lens significantly improves testing efficiency and shortens testing time.

Viewing Angle Measurement Example

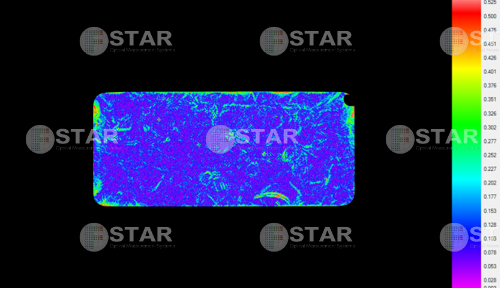

Luminance and Chrominance Analysis

Luminance and Chrominance Uniformity Measurement Example

Luminance and Chrominance Uniformity Measurement Example

The Uniformity Measurement Standard for Displays V1.30 updated by the German Automotive OEM Work Group Displays in 2018 defines the testing and calculation methods for luminance uniformity and Black Mura of automotive displays. Unlike the calculation in SEMI D31, this standard focuses on Black Mura testing under a black screen and uses relative brightness gradient (instead of contrast and area) for calculation to define Black Mura.

Test results should include:

Black Mura Measurement

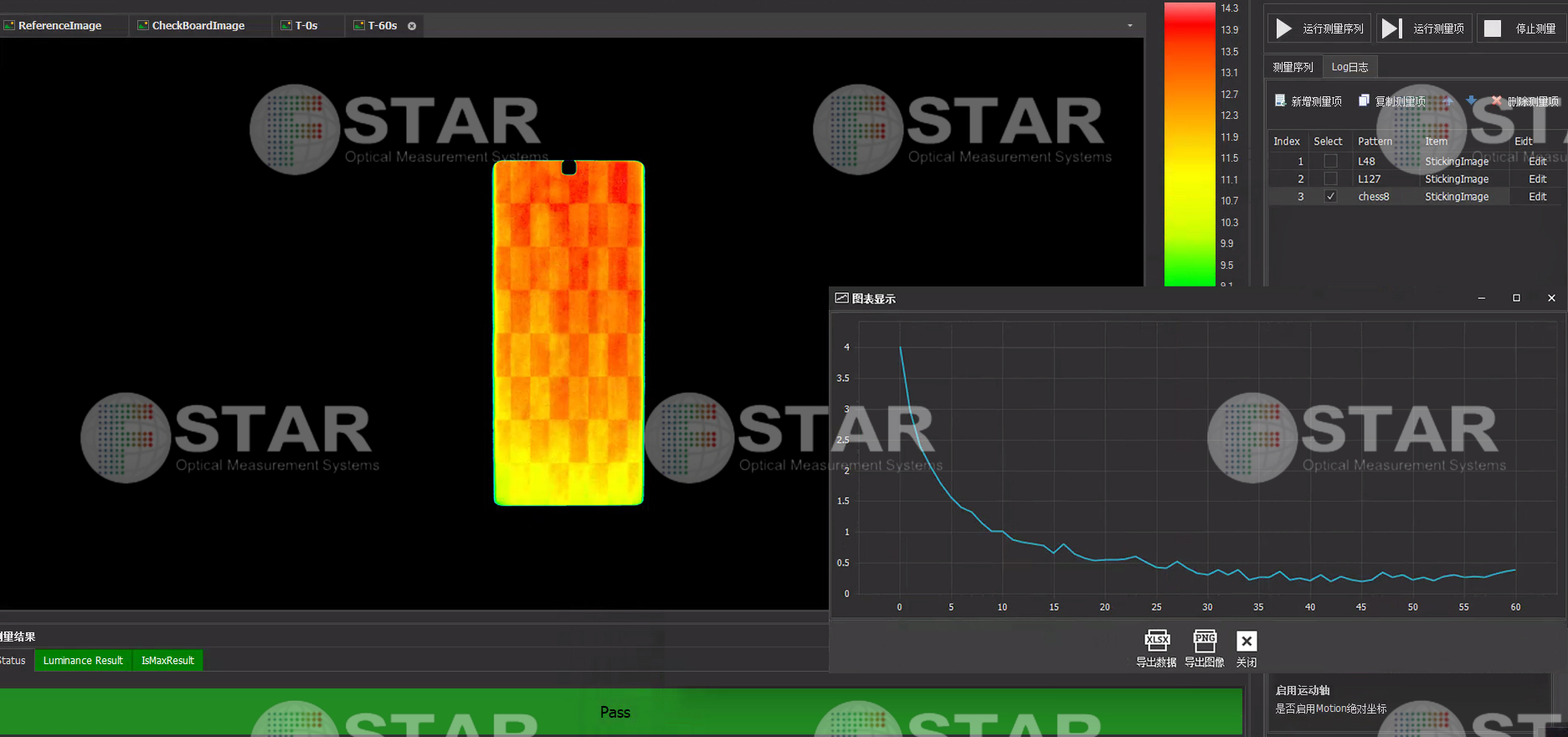

Key challenges in short-term image retention measurement:

Short-Term Image Retention Measurement

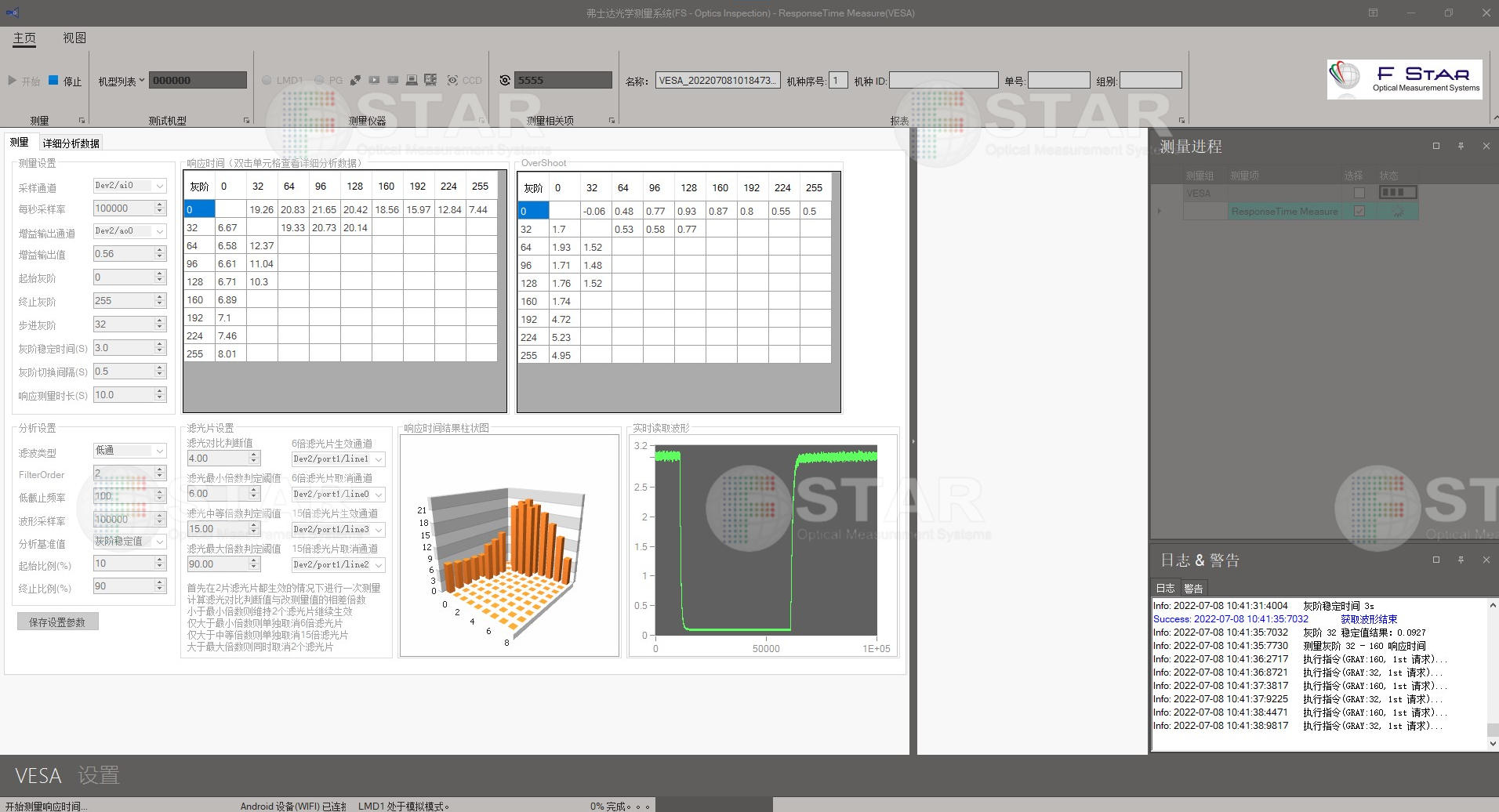

The built-in photoelectric sensor probe has extremely high sensitivity and fast response speed. The collected photoelectric change data is processed for background noise suppression and filtering through a high-performance data acquisition card, finally calculating grayscale response time and Flicker data.

Response Time Measurement

Display defect detection items: black spots, bright spots, bright lines, dark lines, weak lines, foreign objects, stains, image abnormalities, color shift, dents, liquid crystal leakage, etc.

Backlight module defect detection items: white bright spots, black spots, foreign objects, stains, debris, scratches, film displacement, light leakage, black/white shadows, etc.

Defect Measurement

{{data.abstract || "No product introduction available"}}