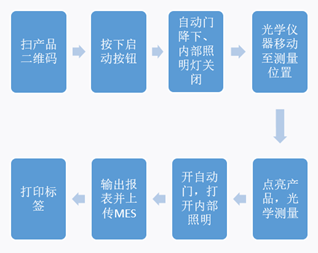

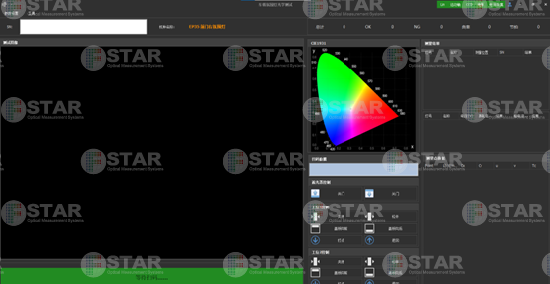

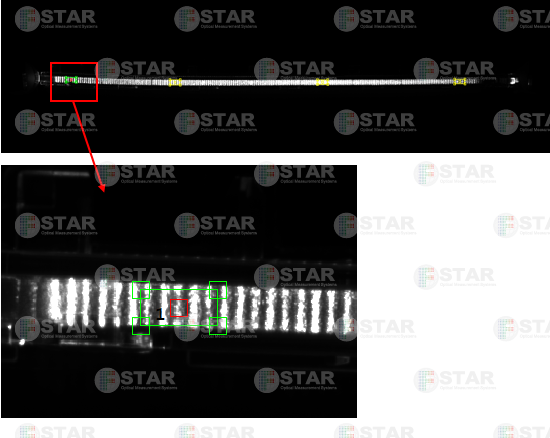

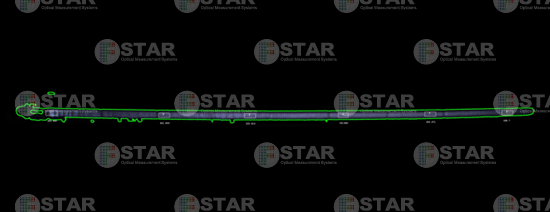

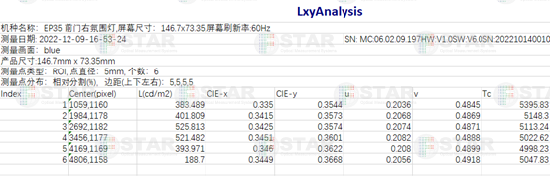

The ambient light testing system developed by Fushida integrates hardware required for testing, such as the DI-1600Si-E Imaging Luminance and Color Analyzer, power supply, light bar bus adapter, barcode scanner, and printer. It realizes a fully automated testing process including barcode scanning, startup, product clamping, door closing, lighting, testing, judgment, data output and upload, and label printing. It can obtain the luminance and chromaticity distribution map of an entire ambient light strip at one time, and can test any specified area as needed.

The Fushida ambient light testing system mainly detects optical characteristics of ambient light products, such as current, voltage, luminance, color, and uniformity. It supports testing of up to two groups of ambient lights and enables point measurement for long strip-shaped, irregularly shaped light-emitting, or light guide strips.

The software of the ambient light testing system supports quick switching of models. Simply scan the QR code on the fixture in the mold barcode scanning area, and the system will automatically switch the current model information and recount the current model (for statistics on yield rate and quantity).

The position, shape, and size of the test area can be fully customized. After editing, it can be saved separately for easy retrieval.

The Fstar ambient light testing system can test multiple products in a single run or test a single product with multiple different colors. It also detects version numbers and bright/dark currents and uploads data, greatly improving efficiency and meeting the operational requirements of stable, efficient, and traceable production lines.

{{data.abstract || "No product introduction available"}}