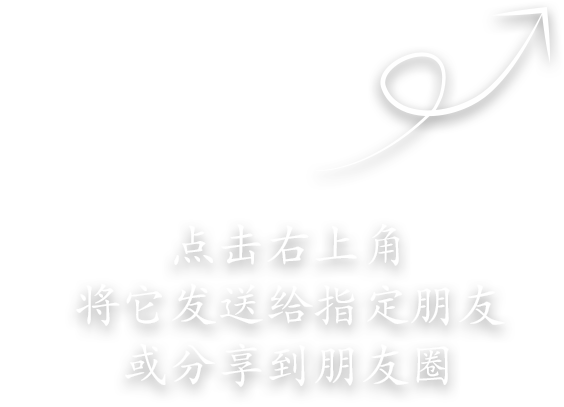

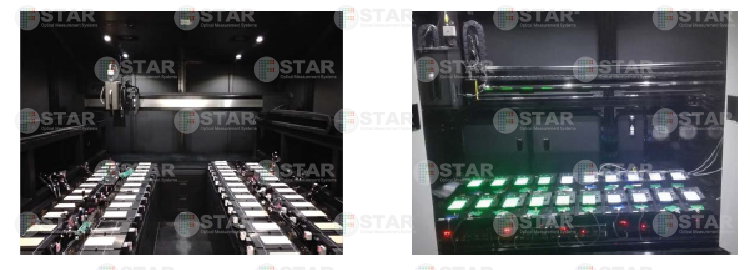

This platform is mainly used for lifetime decay testing of multiple OLED modules for mobile phones or tablets.

Adopts a spectrometer-scanning method to measure parameters under constant temperature (25℃), including luminance, chromaticity (x/y, u'/v'), color temperature, color rendering index, uniformity, current efficiency, image sticking, power consumption, and lifetime. Additionally, the XY-axis scanning measurement method supports testing of lifetime decay and uniformity at multiple different positions on the module surface.

The visual positioning system consists of a CCD positioning system with over 5 million pixels and a high-resolution CCD image observation system. Before each measurement, it automatically scans the placement positions of OLEDs in all stations, identifies the product’s center coordinates and dimensions, with an alignment accuracy requirement of 0.1mm. The CCD alignment is clear, and no manual reconfiguration of each product’s coordinates is needed when switching between OLED products of different sizes.

Temperature monitoring: Optional temperature sensors upload corresponding temperature data during the platform’s optical parameter measurement.

Test items: Luminance, luminance decay ratio, chromaticity values (x/y, u'/v'), color temperature (Tc), emission spectrum, decay time, elapsed testing time, voltage, current, test temperature, RGB function, EL VDD, EL VSS. Curves are plotted, and product service life is predicted based on test data.

Data charts: Voltage-Time, Current-Time, Relative Lv-Time (%), Real Lv-Time, Temp-Time, Efficiency-Time

For products with smooth backs such as flexible screens and flat screens, a porous ceramic vacuum adsorption stage can be used for fixation. The adsorption stage is equipped with a digital vacuum suction gauge to ensure flexible screens are adsorbed flat without causing pixel abnormalities.

For screens requiring temperature control, a patch-type heating platform can be selected.

For screens requiring specific ambient temperature control, a high-temperature chamber can be chosen. It provides uniform ambient temperature control for screens within the limited platform space, with each high-temperature chamber featuring independent temperature control.

To reduce platform size, the platform can be designed with front and rear doors for product loading.

Group testing support: Different groups can be configured with different test items and parameters, and each group can start and stop independently.

Lifetime test time interval and interval setting: Three time intervals and test intervals can be set.

Lifetime test termination condition judgment: Measurement stops when luminance decays to a specified percentage of the initial value, or according to the total time set by the user.

Automatic OLED position identification: Select the test station on the software, and the software controls the industrial visual alignment CCD to automatically scan the size and center position of the OLED light-emitting area at the test station.

Lifetime prediction function: The software has a built-in lifetime prediction formula, which automatically calculates the estimated lifetime based on real-time measured data.

Records voltage/current variation data over time and plots curves (requires PG support for current/voltage detection and software reading).

Real-time saving and recovery of measured data: The software saves data in real time during testing. Even if the computer shuts down abnormally or the software exits unexpectedly, previous data can be loaded and measurement can resume after restarting.

The software can set a group of warm-up images, and the OLED cycles through these images during the waiting period between tests.

Supports barcode scanning and data upload to the server (upload protocol to be provided by the customer).

Powerful software testing functions: Users can edit combinations of arbitrary positions, arbitrary images, and arbitrary test items, meeting requirements for lifetime testing, uniformity testing, and aging testing under different images.

The program supports independent front-end and back-end programs + database storage system.

{{data.abstract || "No product introduction available"}}